Brinell Hardness

Units

The hardness measurement according to Brinell

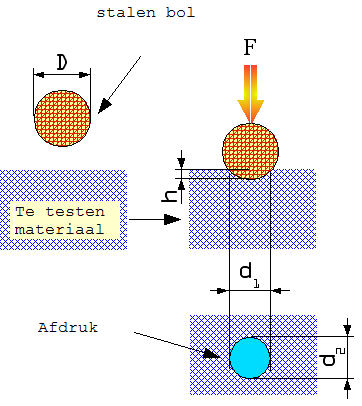

With Brinell hardness measurement, a steel or carbide ball is pressed into the material to be tested. The size of the depression is a measure of the hardness of the material. The diameter of the depression is converted into a number called the “Brinell Hardness” using a formula.

The diameter of the steel ball must always be matched to the material to be measured. The underside of the material must not deform during measuring. To enable a clear reading, the depression should not be too deep. The difference in impression would become too difficult to see. A minimum compression is another requirement. The diameter of the depression should be between 0.2 and 0.7 times the diameter of the ball. Standard diameters are: 1, 2.5, 5 and 10 mm.

Calculation of hardness according to Brinell:

The Brinell hardness can be calculated using the diameter of the ball, the diameter of the depression and the load on the ball.

HB = (0.102 x load)/area of indentation

HB = 0.102 x F/A

| HB | = | the hardness according to Brinell |

| 0,102 | = | a conversion factor. In the past the force was expressed in kgf, nowadays in Newton. To achieve the same Brinell hardness, a conversion factor is required. |

| F | = | the force on the ball in N |

| A | = | the area of the depression in mm2 |

| D | = | the diameter of the bullet |

| d | = | the diameter of the depression |

Indication of hardness according to Brinell:

Indication : 300 HB

This designation is used to indicate a measurement with a ball diameter of 10 mm, a test load of 29420 N and a load time of 10-15 s. This is a commonly used measurement.

Indication : 200 HBS 10/3000/15

- 200 hardness value

- HBS test according to Brinell performed with a steel ball

- 10 diameter of the bullet = 10 mm

- 3000 load (= 3000/0,102) N = 29 410 N

- 15 duration of the test = 15 s

Indication : 350 HBW 5/250/30

- 350 hardness value

- HBW test according to Brinell performed with carbide ball

- 5 diameter of the bullet = 5 mm

- 250 load = (250/0,102) N = 2451 N

- 30 duration of the test = 30 s

Properties of the Brinell hardness measurement:

- The Brinell hardness measurement is limited by the deformation of the ball. With materials harder than 500 HB, the ball will deform.

- By using a fairly large depression (ball 10 mm), it is possible to measure the hardness of non-homogeneous materials. This is important for measurements on cast iron.

- There is a relationship between hardness and tensile strength. For steel Rm = 10/3 HB. For aluminum Rm = 0.55 HB